Life Cycle Assessment (LCA) is a methodological approach aimed at evaluating the potential environmental impacts associated with a product, from its initial raw material extraction phase to its ultimate disposal as waste.

Conducting an LCA analysis offers several advantages. Primarily, it enhances the accuracy of data and promotes cross-company comparability. Furthermore, increased transparency and documented evidence can counteract greenwashing and misleading claims of sustainability. Lastly, it empowers consumers to evaluate the environmental friendliness of a product.

The role of LCA in Danish Crown

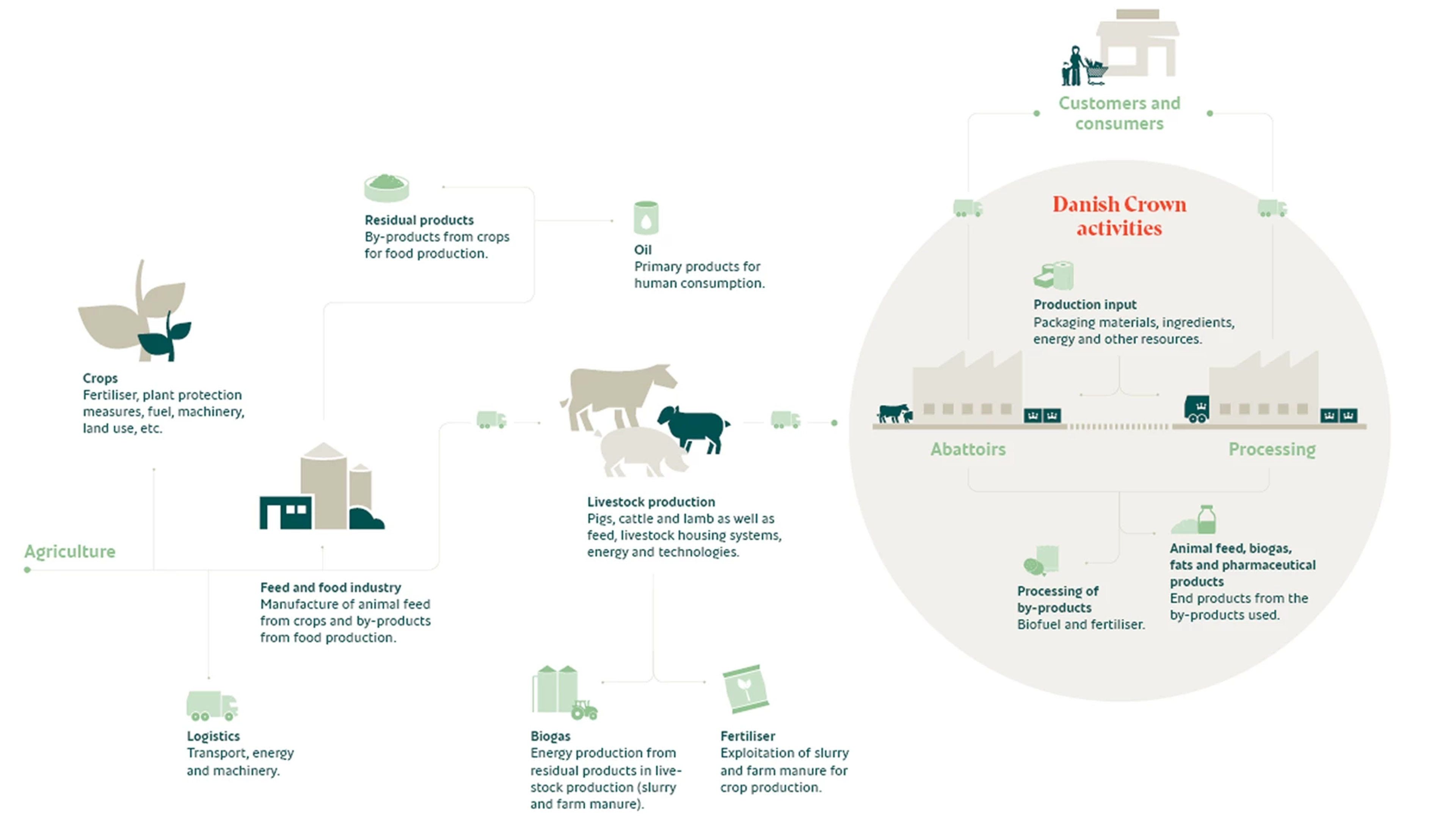

Currently, Danish Crown stands out within the meat industry due to our advanced LCA model, which is supported by a vast amount of primary data spanning across our value chain. This makes the model a valuable tool that can guide us in our efforts to reduce our emissions. For example, the implementation of LCA modelling at Danish Crown has enabled:

- Calculation of product environmental footprints, facilitating climate emission monitoring.

- Communication of sustainability progress backed by validated data.

- Identification of supply chain hotspots and formulation of effective reduction strategies.

- Prioritisation of initiatives across the organisation

The model also empowers us to effectively support our clients in reducing their emissions. For instance, we can calculate not only the carbon footprint per kilogram of meat but also the carbon footprint of specific selected products using data from suppliers, abattoirs, processing facilities, and transport companies.

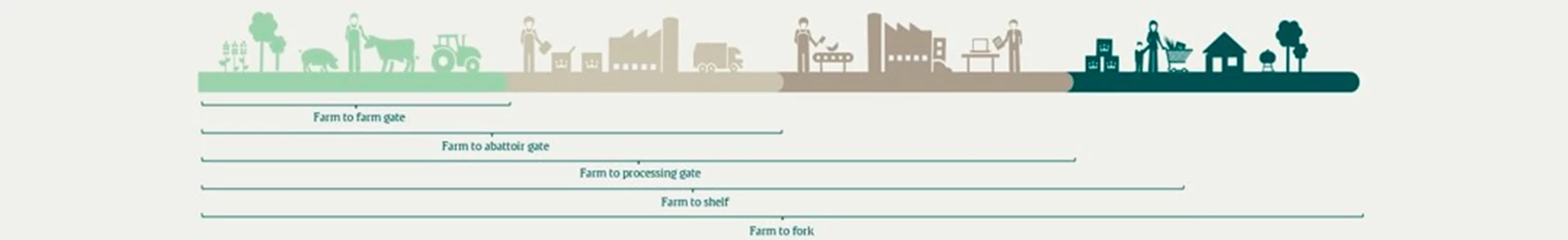

The scope of LCA depends on chosen system boundaries

The scope of a product's lifecycle can vary from company to company, depending on chosen system boundaries. In our industry, the different system boundaries that can be used include farm-to-farm gate, farm-to-abattoir gate, farm-to-processing gate, farm-to-shelf, or farm-to-fork. This choice of scope directly influences the functional unit considered. For instance, a farm-to-farm gate approach assesses the environmental impact of the live weight of an animal, while a farm-to-processing gate assessment provides insight into the environmental footprint of processed products like bacon or pepperoni.

In Danish Crown's model, the system boundaries encompass the entire production process from farm to the processing gate for beef and pork products. LCA results within this context can be derived at three significant points in the product lifecycle: 1) at the farm gate, 2) at the abattoir gate, and 3) at the processing gate.

Deep dive into the Danish Crown LCA model

Danish Crown's approach to LCA is comprehensive, encompassing primary data on feed production, livestock farming, abattoirs, logistics, and upstream inputs such as fertilizers, chemicals, fuels, electricity, and machinery. Wherever we have primary data, we employ detailed modelling (foreground systems), which is then supplemented with secondary data, such as emissions from electricity consumption (background systems).

Farm-level data plays a central role in our model and serves as an excellent example of how primary and secondary data interact within our model: For countries and animal categories covered by the Climate Track, a significant portion of the farm-level data is collected directly from individual farmers. In cases where individual farmer data is not available, we populate the model with national average data. This national average data serves as a benchmark for calculating the environmental impacts of pork and beef production at the farm gate, facilitating comparisons between individual farms and national averages.

This LCA tool is developed for products originating from Danish Crown's key markets of operation: Denmark, Sweden, Germany, and Poland. Additionally, the model can potentially be expanded to include more countries in the future.

Third-party verification and alignment of our model with international standards

Danish Crown's LCA model defaults to a cause-effect-based model in line with ISO 14040 and 14044 standards, combined with a consequential modelling approach. Furthermore, the model can be adapted to calculate results based on the attributional model, specifically the EU Product Environmental Footprint (PEF) Guideline developed by the European Commission. Different purposes may require different LCA methodologies. When making decisions, a cause-effect-based approach is needed. Conversely, business-to-business LCA data often needs to align with specific guidelines, such as the EU PEF Guideline.

In 2021, Danish Crown initiated the development of our own LCA tool. The tool has been validated by independent entities, including the University of Southern Denmark, Aarhus University, and Novozymes A/S.

Maintenance and updates to the model

Recognising the critical importance of maintaining accuracy, Danish Crown remains committed to continually refining the LCA model. This ongoing commitment involves regular updates and thorough documentation of any modifications made. Anticipated improvements aim to not only enhance accuracy but also deliver more precise calculations and outcomes tailored to specific products. Improvements in the model and data may lead to changes in LCA values compared to previous calculations. To document the effect of model updates on LCA values, we record model changes and aim to implement them within clearly defined time spans.